CHAVA differentiators

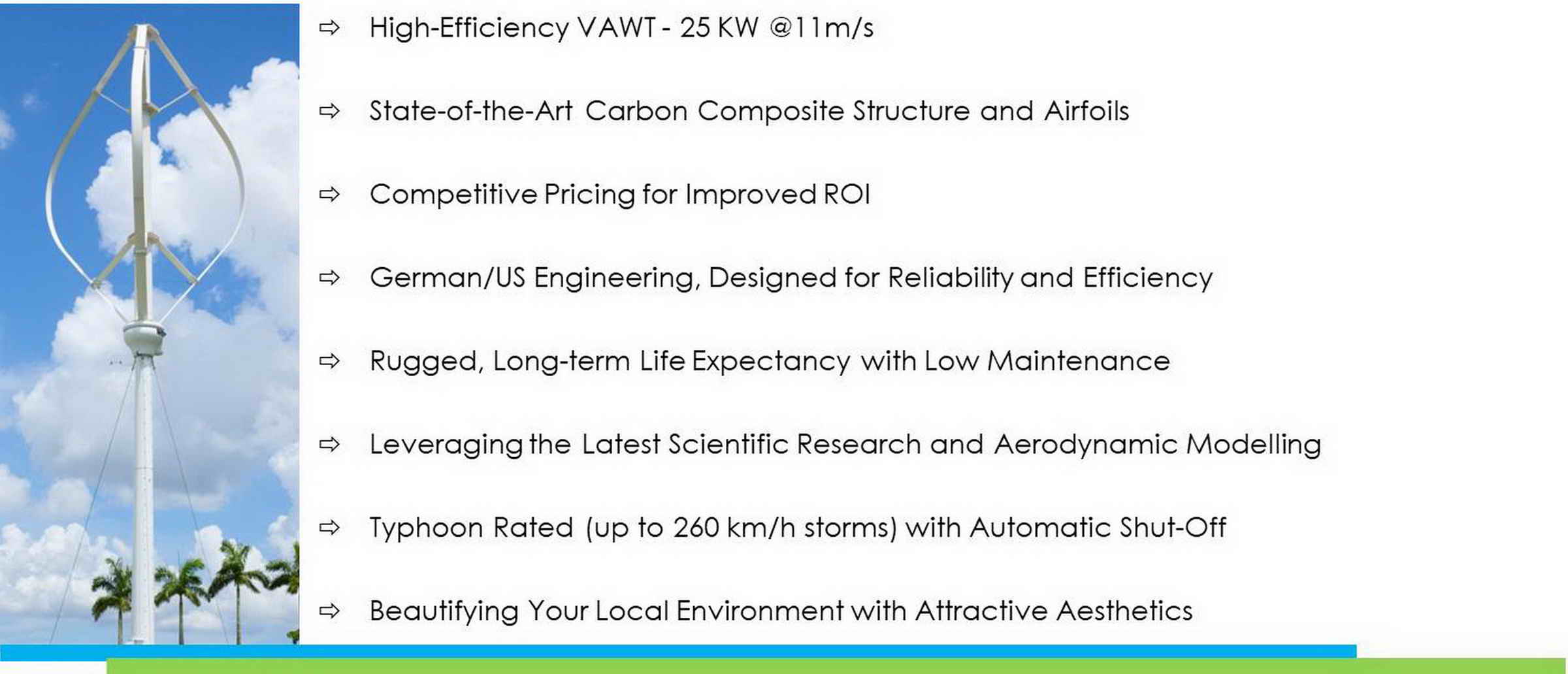

At CHAVA, we believe that wind power shouldn’t be in contradiction with good aesthetics and community values. One of the biggest hurdles to the adoption of wind energy is the NIMBY (Not in My Backyard) phenomenon: namely, resistance from local communities against unsightly, visually intrusive Horizontal Axis Wind Turbines (HAWTs). Manufacturers haven’t innovated enough on the blending of technology and aesthetics, and as a result, many communities are now fighting back against ugly wind turbine eyesores.

The Troposkein airfoil shape emerges from the union of physics and geometry, and it describes the curve that an idealized rope assumes when anchored at its ends and spun around its long axis at a constant angular velocity. The fundamental advantage of a Troposkein airfoil shape is the fact that it is only subjected to tension forces during rotational motion and no bending forces. In the past, in spite of these promising potentialities, VAWTs have been considered structurally challenging, unreliable, and low efficiency.

CHAVA has injected advances in composite material and carbon fiber fabrication methods and engineering insights based on the latest aerodynamic modelling techniques developed by the world’s leading research scientists to deliver a robust design solution at low cost with high structural reliability, providing our customers with a cutting edge wind turbine that combines the classical advantages of VAWTs (much lower noise and bird kill, no yaw system, and better aesthetics) with the efficiencies and reliability typical of more common HAWT systems.

CHAVA’S Small Wind VAWT is rated at 25 KW of electrical power at 11m/s wind speed and can withstand storms of up to 280 km/h. CHAVA Wind’s innovative engineering solution to the Troposkein profile avoids premature bearing failure by spreading both horizontal and vertical forces along the length of its axis, for lower vibration, greater durability, giving the CHAVA Wind turbine a rare tranquility not found in ordinary wind turbines.

The hydraulic tilt mast system will not only reduce installation and maintenance cost substantially, it will furthermore enable the creation of local installation/maintenance jobs, as the highly specialized and scarce climbing and harnessing skills of the maintence staff is no longer required.